Hygiene management by Hypochlorous acid

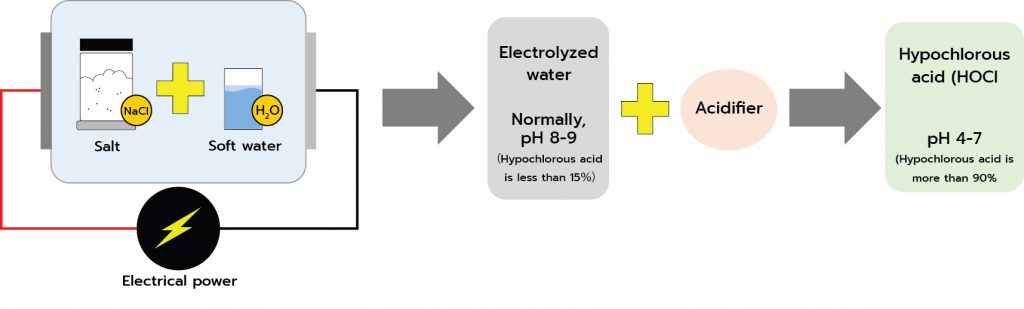

Disinfectant technology from ClohSei® and AquaRiserTM generates Hypochlorous acid which is the natural powerful oxidant that white blood cell creates to kill pathogens. Our technology, however, uses only food grade raw material unlike some other technologies. We apply electrical power into saline with appropriate concentration to generate electrolyzed water and then mix with acidifier to do pH adjustment in order to keep large existence ratio of Hypochlorous acid.

Hypochlorous acid in weak acid solution

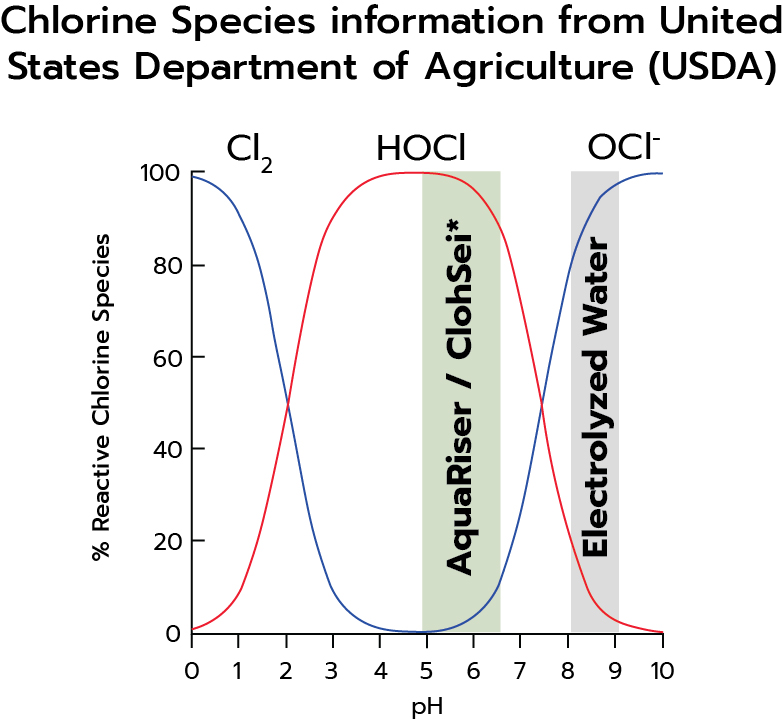

Although there are many technologies of Hypochlorous acid generation, some of them generates output solution with pH range of 8-9 especially saline electrolysis method.

Many handheld or portable device claimed to be Hypochlorous acid generator but output solution has pH around 8-9 which has only less than 15% of Hypochlorous acid. At this range of pH, most of active agent is Hypochlorite ion which has much less effectiveness in disinfection. We called this output solution as “Electrolyzed Water“.

Our saline electrolysis technology (ClohSei® / AquaRiserTM) has acidification technique to make pH of the output solution in range of 4-7 (mostly 5-6.5) which is in weak acid region. At this range of pH, most of active agent is “Hypochlorous acid” and its existence ratio is more than 80%. Our technology makes existence of Hypochlorous acid more than 6 times of ordinary Electrolyzed water.

Comparison of Hypochlorous acid generation technologies

As mentioned earlier, there are many technologies to generate Hypochlorous acid. Hypochlorous acid, itself, is safe and very effective in killing pathogens without any toxic residue if it is generated by method that keeps high existence ratio of Hypochlorous acid. Some technologies, however, create unwanted by product, or require hazardous raw material, or generates toxic chlorine gas. Although output solution is safe, handling risk of unwanted substances is still necessary.

Our technology does not require any handling with hazardous substances, unlike some other technologies. We provide cleaning technology of Hypochlorous acid generation which has no risky raw material, and no unwanted by product. No handling risk requires at all.

Comparison of electrolysis system between membrane and non-membrane

- Electrolysis without membrane using saline: Generates Electrolyzed water and there is no unwanted by product such as Caustic soda. Hypochlorous acid can be obtained with pH modifier additive.

- Electrolysis without membrane using hydrochloric acid: Generates Hypochlorous acid but concentration is normally less than 60ppm. However, raw material is harmful substances which must be well handled.

- Electrolysis with membrane using saline: Generates Hypochlorous acid with pH 2-3 which comes up with toxic Chlorine gas in one chamber and also generates Caustic soda (unwanted by-product) in another chamber.

- Acidified sodium hypochlorite: Obtains hypochlorous acid with pH modifier additive but Chlorate may come out after keeping it for a while.

Outstanding features of ClohSei® and AquaRiser

- Our Hypochlorous acid existence rate is approximately 6 times higher than ordinary “Electrolyzed water”.

- Our technology is flexible in concentration tuning from 1ppm to hundreds ppm.

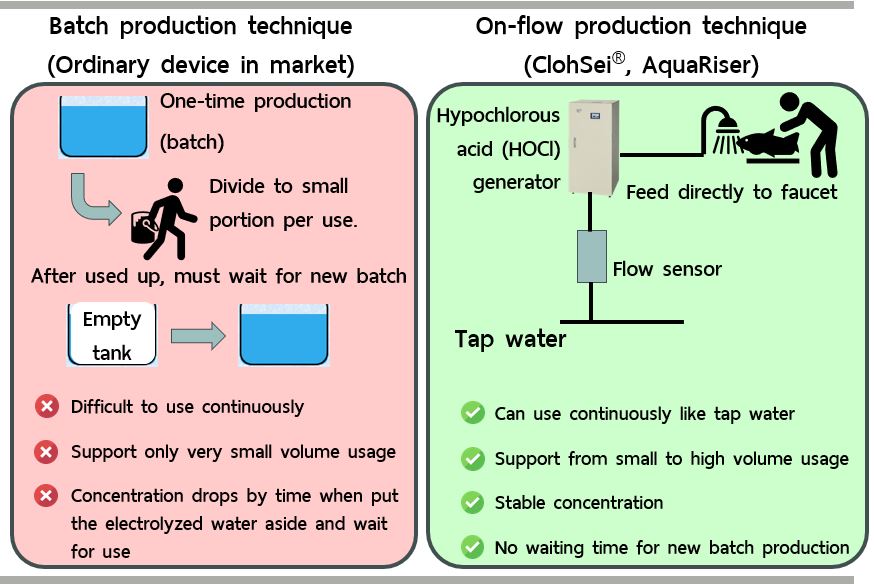

- Both ClohSei® and AquaRiser keeps stable concentration. Unlike other technologies, concentration of our Hypochlorous acid does not vary by water flow rate.

- Our device generates Hypochlorous acid at a glance, not batch production. Users can continuously use Hypochlorous acid, no need to wait for the next production batch.

- There is no need to contact with any hazardous raw material.

- There is no any toxic residue and no unwanted by product.

- After killing pathogens or contact with organic substances, our Hypochlorous acid will be dissolved into water. There is salt content less than 0.02%.

- There is no chlorine gas production, or chlorate contamination.

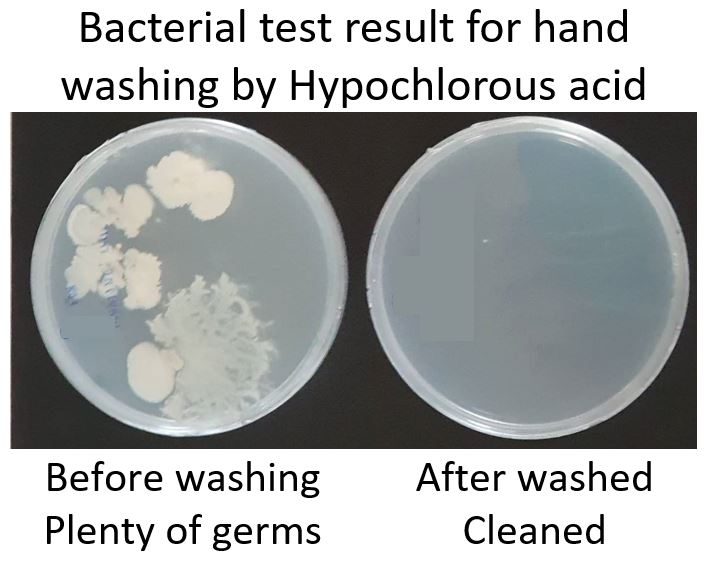

Effectiveness in killing bacteria, virus, and fungi

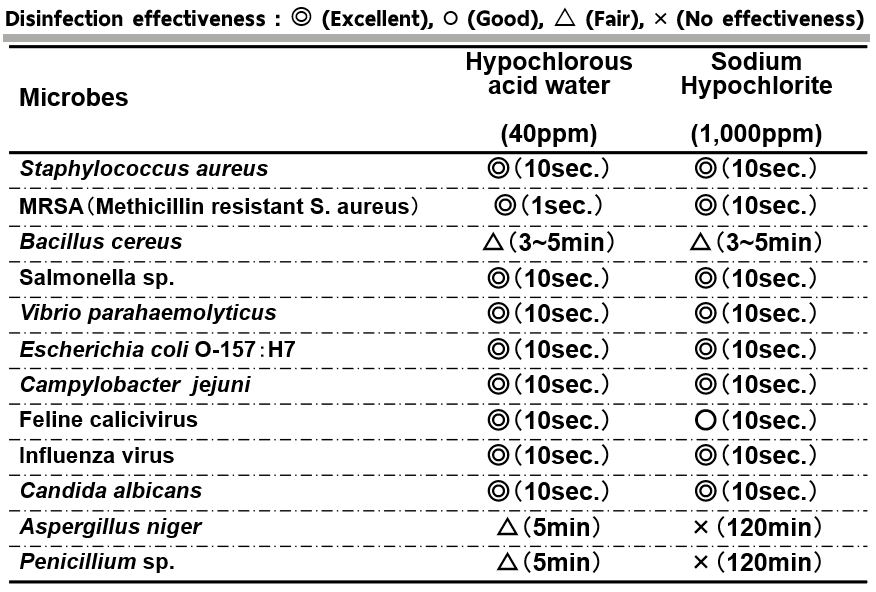

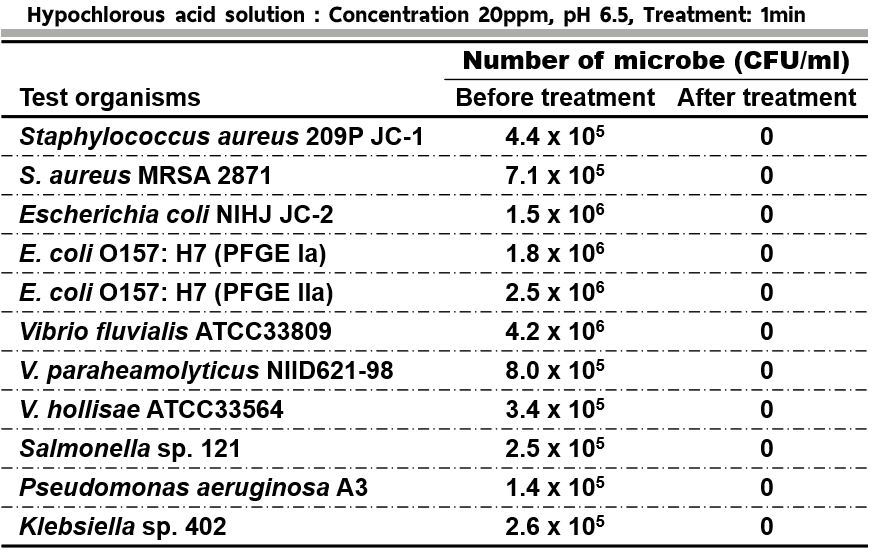

Hypochlorous acid is well known as natural powerful oxidant agent in human immunity system. It can kill 99.99% of bacteria, virus, and some kinds of fungi and its spore with very small contact time. When comparing with Sodium hypochlorite, Hypochlorous acid requires much less concentration (ppm) but has better disinfectant function and no toxic residue after used. There is no need to rinse by water afterward, unlike other disinfectant agents.

Usage example of Hypochlorous acid

We can replace chlorine usage (Sodium Hypochlorite) with Hypochlorous acid. So that there are many actual applications since our technology (AquaRiser) has more than 20 years of usage history in Japan.

Support various sizes of usage

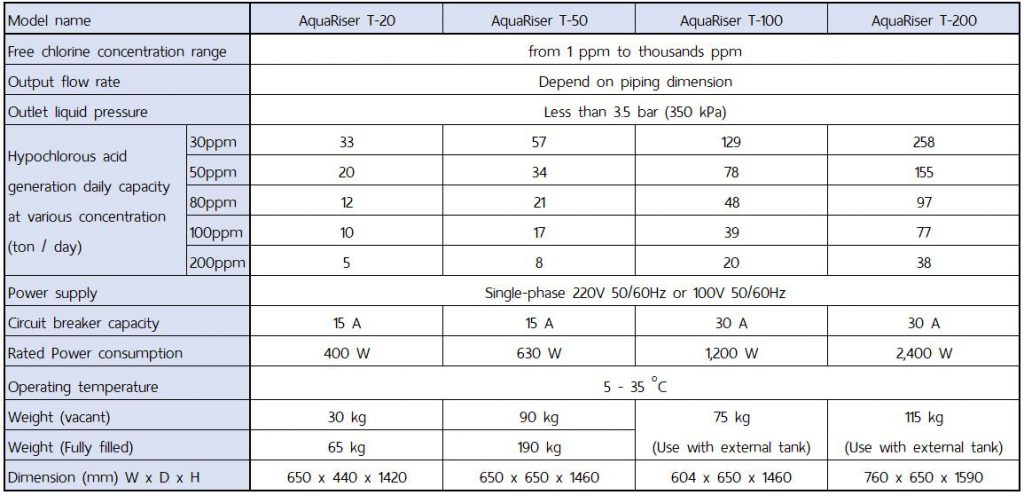

AquaRiser serves needs of high-volume usage; for example from 33 tons/day (30ppm) until 258 tons/day (30ppm). At this rate of production, we can wash vegetables, meats, and any food ingredients up to 3,300 kg per day with the smallest size of AquaRiser. The largest size of AquaRiser can wash food ingredients up to 25,800 kg per day. The equipment suits well to food processing factory, hospital, or large scale of facility center.

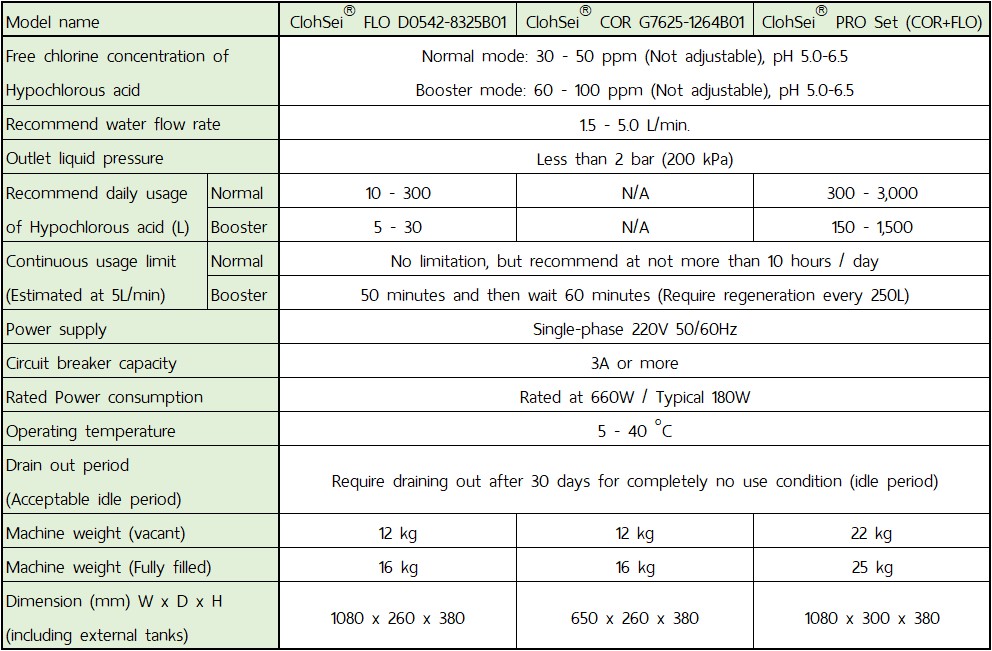

ClohSei® serves home, restaurant, veterinary clinic, and ordinary users which requires only small-volume usage of 90-300 liters/hour at concentration range of 30-50ppm for water flow rate range of 1.5 to 5 liters/minute. We recommend ClohSei® equipment if using rate is less than 3 tons/day (30-50ppm) which can wash food ingredients up to 300 kg per day.

Specification for each model of AquaRiserTM & ClohSei®