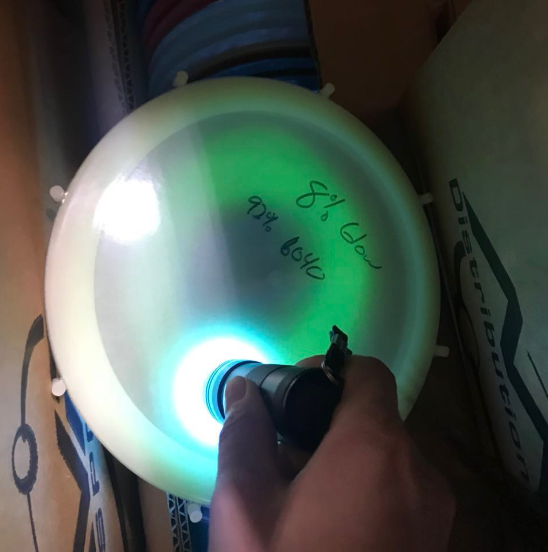

Glow Masterbatch

We also have glow masterbatch in our product line-up. Mixing ratio of base plastic per glow pigment is 1 by 1 (50% by weight). Glow masterbatch is good for plastic injection manufacturing in order to create your own glow product. Base plastic material can be selected from the list below. Glow pigment material is Strontium Aluminate which provides high glowing performance, last long and also safe for human and animal-being. This material is much different with Zinc sulfide which is low performance and cheap material. Zinc sulfide is quickly excited but the glowing light fades quickly also. Nexit® glow masterbatch becomes much better choice in term of performance. Besides, our glow pigment meets EN71-3 standard. So that it can be used in toy manufacturing process based on European standard.

For compound manufacturing factory, Nexit® glow masterbatch is good for mixing further with base resin to produce glow compound pellet of your own.

Luminance level of Nexit® glow masterbatch

Glowing level of masterbatch depends on mixing ratio of glow pigment and base plastic material, and also transparency of base plastic material. Nexit® glow masterbatch can be customized as customer’ needs. Here are our main base plastic for making glow masterbatch.

| Luminance level after dark (mcd/m2) | 2 min. | 10 min. | 30 min. | 60 min. | Class of standard |

| Glow ABS (Model: NGABS-G520-50) | 1,938 | 520.6 | 169.8 | 78.4 | DIN 67510 Class D |

| Glow EVA (Model: NGEVA-G590-50) | 2,200 | 589.5 | 190.8 | 87.3 | DIN 67510 Class E |

| Glow PVC (Hard PVC) (Model: NGPVC-G270-H50) | 1,039 | 274.6 | 87.9 | 39.9 | DIN 67510 Class C |

| Glow PVC (Soft PVC) (Model: NGPVC-G490-S50) | 1,829 | 493.9 | 162.0 | 74.3 | DIN 67510 Class D |

| Glow PE (Model: NGPE-G520-50) | 1,983 | 518.8 | 165.1 | 74.8 | DIN 67510 Class D |

| Glow PMMA (Model: NGPMMA-G550-50) | 2,062 | 552.7 | 182.0 | 84.9 | DIN 67510 Class D |

| Glow PP (Model: NGPP-G570-50) | 2,142 | 570.4 | 187.5 | 84.9 | DIN 67510 Class D |

| Glow TPU (Model: NGTPU-G510-50) | 1,885 | 516.4 | 166.1 | 75.2 | DIN 67510 Class D |

Usage example of glow masterbatch in injection molding