What is glow material?

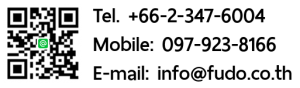

There are 2 types of glow material which are reusable type and non-reusable type.

Reusable type of glow material absorbs light and then glow in the dark surrounding. After the light is all released from the material, it can be recharged with external light to reuse it. Currently, there are two main categories of glow material in this type.

👉 Zinc Sulfide: This material is original one which has small bandgap. So that it can absorb light very fast but the light is gone very fast too.

👉 Strontium Aluminate: This material has much larger bandgap compare with Zinc Sulfide which enable larger light energy storage in the material. Therefore, this material can prolong glowing time and has much better luminance than Zinc Sulfide.

Meanwhile, non-reusable type of glow material is basically glow from its chemical reaction or even some may have radioactive particle releasing and decay as time passed. In this page, we are focusing on the reusable type of material.

Mechanism of glowing property

Glow-in-the-dark material or photoluminescent material has its glowing property by absorbing light energy and release that energy in form of light wave in the dark environment without any Electrical power required. Hence, the glow material has great benefits in term of following.

- Using glow material does not require Electrical power. So that, it helps reducing carbon dioxide emission and good for environment.

- Since it can glow without Electrical power, photoluminescent (glow-in-the-dark) product is easy to install. No Electrical system construction.

- No cost during usage. There is cost at initial installation only.

- No timely maintenance cost such as light bulb or battery changing cost.

Difference among Glow, Reflective, and Neon material

| Glow material | The material absorbs light energy and then release that energy in form of light wave. The material with glow property can glow-in-the-dark by itself after enough light absorption. The glowing light intensity is decayed by time. |

| Reflective material | The material with reflective property reflects any incident light to be visible in the dark (external light source is necessary). This type of material does not glow and invisible without external light incident. |

| Neon material | The material with this property response to excitation light source to be visible as glowing in the dark (external light source is necessary). Thus, the material will not glow without external light source (glow only in excitation condition). |

Lifetime of glow material

Ordinary glow material is semi-permanent material which can last long but cannot tolerate humidity and water. Glowing property is dissolved by water. Normally, glow material and glow products are recommended to be used in indoor condition.

However, glow material from LumiGLOW® is manufactured by Strontium Aluminate which is semi-permanent material with water-resistive coating in pigment level. It is non destructive material and resistance to UV light. There is no significant degradation even tested under condition of Sunshine Weathering condition for 1,030 hours (equivalent to 5 years).

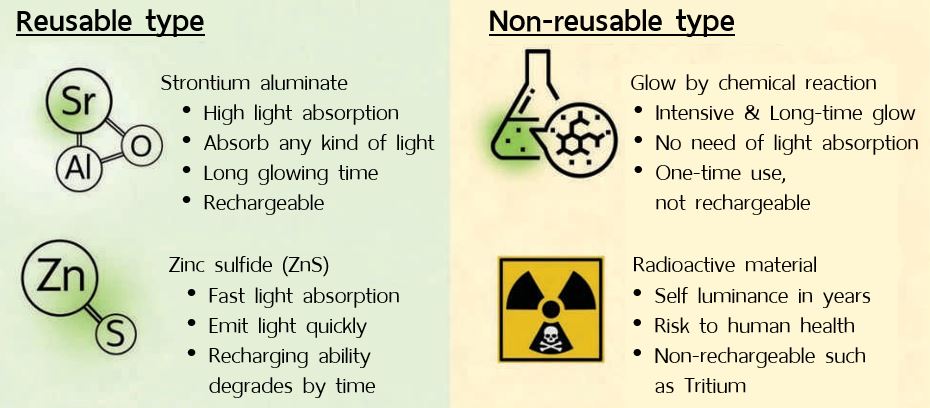

Applicable light source

Glow material from LumiGLOW® is Strontium Aluminate which has property of light absorption for wavelength from 200nm to 480nm. This range of light wavelength covers from UV ray, LED light bulb, fluorescent lamp, and even tungsten light bulb. Since it is good to apply with many kinds of light, the glow material from LumiGLOW® can be used in various types of application.

Glowing time of material

How long does it glow?

How many hours will it last long?

There are these kinds of question from our user very often. Our straight answer is “cannot not specify” because visibility of glow material depends on luminance level of the excited light source. Normally, glow material has its luminance which is measured in unit of milli-candela per square meter (mcd/m2). Visibility at each luminance level depends on observer. We performed blind visibility test in order to investigate minimum level of luminance level that can be seen by human as following table (sample group of 10 persons).

| Luminance level (mcd/m2) | Visibility condition under dark environment | Number of sample that can notice light spot | Number of sample that is unable to spot light source |

| 200 or above | Text readable | 10 persons | 0 persons |

| 5 or above | Text noticeable | 10 persons | 0 persons |

| less than 3 | Visible glow spot | 10 persons | 0 persons |

| less than 2 | Able to notice glow spot | 10 persons | 0 persons |

| less than 1 | Almost impossible to notice glow spot | 3 persons | 7 persons |

| 0.3 | Equipment low limit | — | — |

From the above table, we draw visible line for LumiGLOW® product at luminance level of 3 mcd/m2 or above, according to measurement method in global standard such as DIN 67510, JIS Z 9107, ISO 17398.

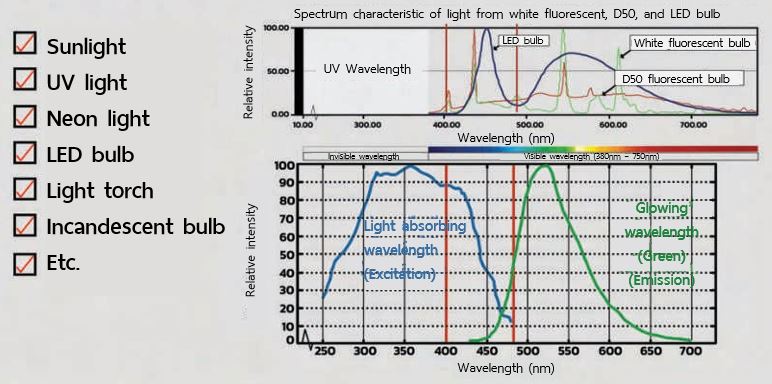

Concern on standard class rather than “Glowing hour”

There are many sellers who claim “glowing hours” in the product description without specify experimental conditions. Although two sellers claim the same number of glowing hours, the actual glowing time may be totally different.

Glowing time depends on absorbing light intensity, light absorbing time, usage condition in the dark (completely dark or partially dark), mixture ratio of glow pigment in the products, and quality of used glow pigment.

So the same excitation condition and luminance measurement condition should be specific to be the same condition among each material in order to compare glowing time and performance. Global standards such as DIN67510, JIS Z 9107, ISO17398 determine light excitation condition and measurement condition already. If you need to compare performance of glow materials, please make sure that you compare them under the same standard number and class.

LumiGLOW® product has weatherability test report to ensure product endurance and many more tests.

LumiGLOW® passed various global standards; for example

- Water resistance test: Submerge a piece of LumiGLOW® sheet for 1 month. It is found that the glowing performance has no significant change.

- Weatherability Test: Do cycle test according to JIS A 1415 standard by spray water for 18 minutes and then shine light with intensity of 180W/m2 by Xenon arc lamp for 102 minutes under ambient temperature of 63 Celcius centigrades and 50% humidity. There is no significant change in glowing performance after repeat this cycle for 1,000 hours (equivalent 5 years of outdoor usage).

- Adhesive Test: Perform test by following methodology in JIS Z 0237 standard for both indoor and outdoor conditions.

- Flamability Test: Perform test by following methodology in ASTM E 162-95 standard.

- Smoke Intensity Test: Perform test by following methodology in ASTM E 662 standard.

- Toxic Gas Generation Test: Perform toxic gas generation by following methodology in SMP-800C standard

- Luminance Test: Perform test by following methodology in various global standards; JIS Z 9107, DIN 67510, ISO 17398

- Luminance Test (Outdoor): Perform test by following methodology in JIS Z 9098 standard and ISO 22578 standard

- Hazardous substances detection: Perform hazardous substances according to RoHS 2.0 standard which is widely applied in US, Europe, and worldwide in order to ensure that glow materials and products from LumiGLOW® and Nexit® are highly safe for human, animal-being and environment (Green product).